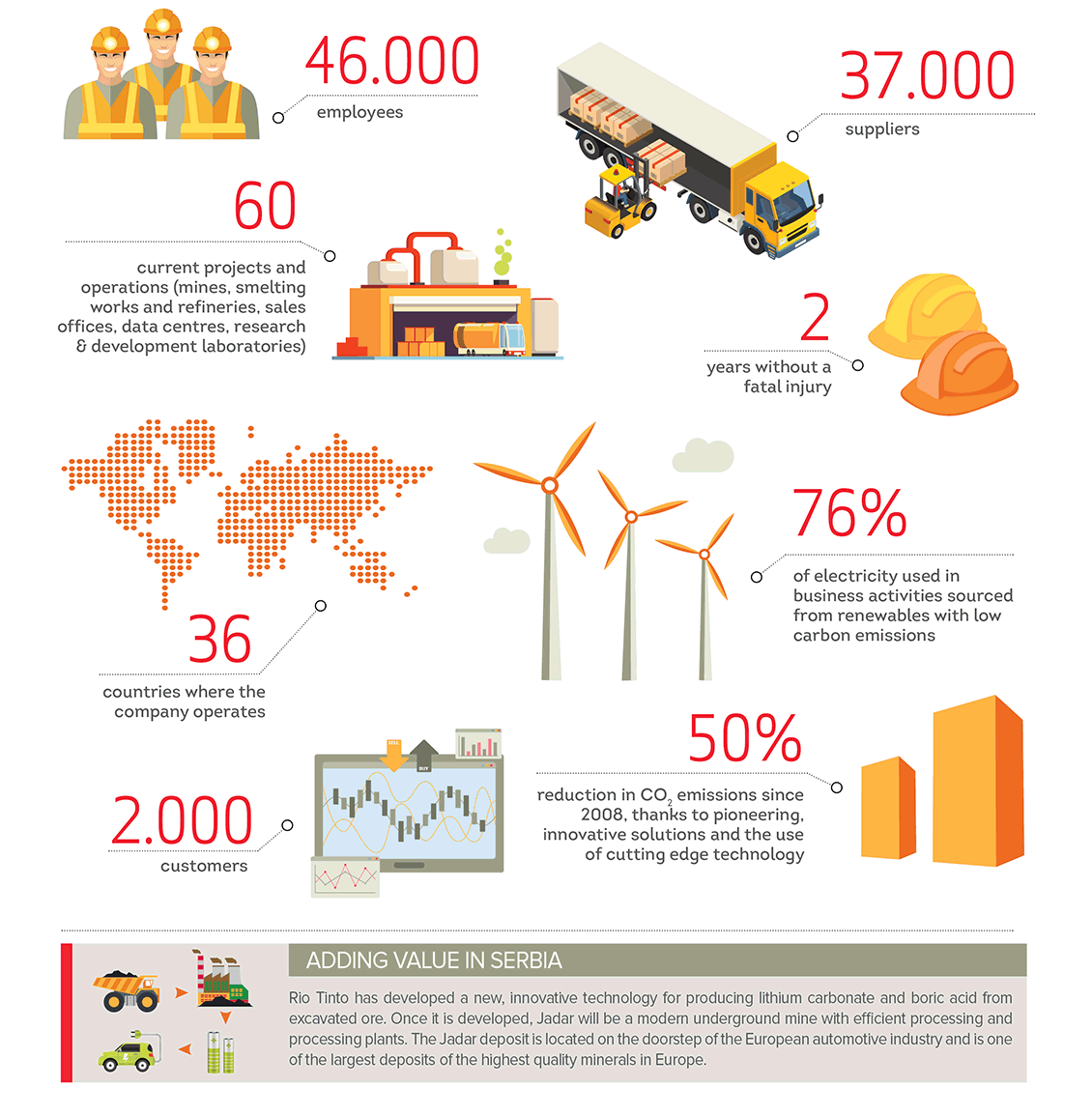

Rio Tinto is one of world’s leading mining companies with operations in over 35 countries worldwide. Rio Tinto has a strong focus on sustainability and products for the future, such as lithium, which sits at the heart of the energy storage and electric vehicle revolution.

Rio Tinto launched its first integrated sustainability strategy in 2018, which obliges the company, in its own words, to adopt high standards, because the issue of sustainability is crucial for its operations, employees, the communities in which it operates and the customers who use its products. Rio Tinto implements the strategy by conducting safe, responsible and profitable business operations, cooperating with partners and customers and producing pioneering materials for human progress. Rio Tinto strongly supports the development agenda for 2030 and the sustainable development goals (SDGs) proclaimed by the United Nations (UN). Leveraging innovative technology and solutions, Rio Tinto has reduced CO2 emissions from its operations by 50 per cent since 2008, and 76 per cent of the electricity used by the company now comes from renewable sources with low carbon emissions.

CARE FOR PEOPLE AND THE ENVIRONMENT

Health and safety are Rio Tinto’s foremost priorities. That’s why it has strictly defined standards, processes and procedures to protect the health and safety of the people, environment and communities in which it operates.

The business prioritizes the rights and welfare of employees, ethics and integrity in business, respect for every link in the supply chain, but also respect for, and preservation of, the environment. Transparency in doing business is also important to this company, as the foundation to building trust with stakeholders.

Maintaining and increasing profitability is also crucial for Rio Tinto, because only a profitable business can create sustainable, long-term value – not only for shareholders, but also for communities, governments and employees.

PARTNER TO SERBIA

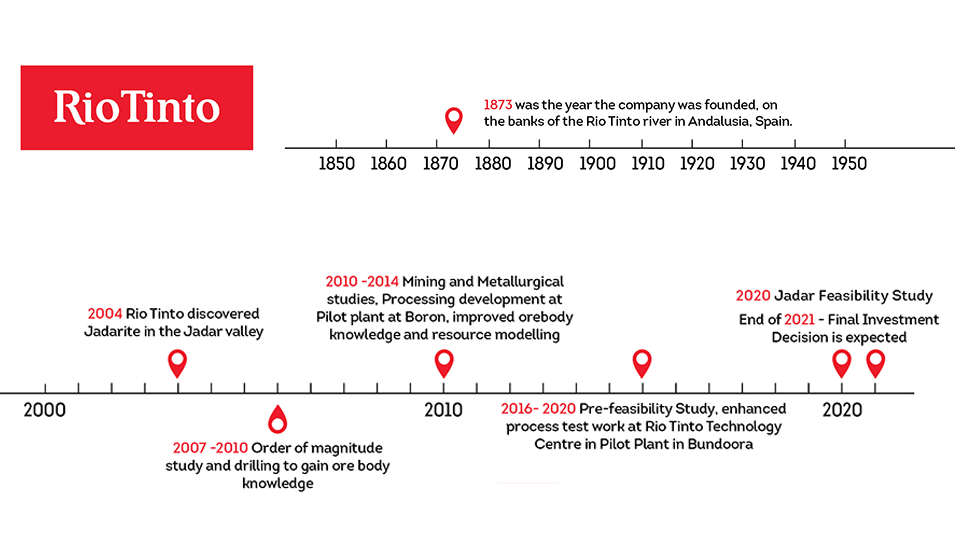

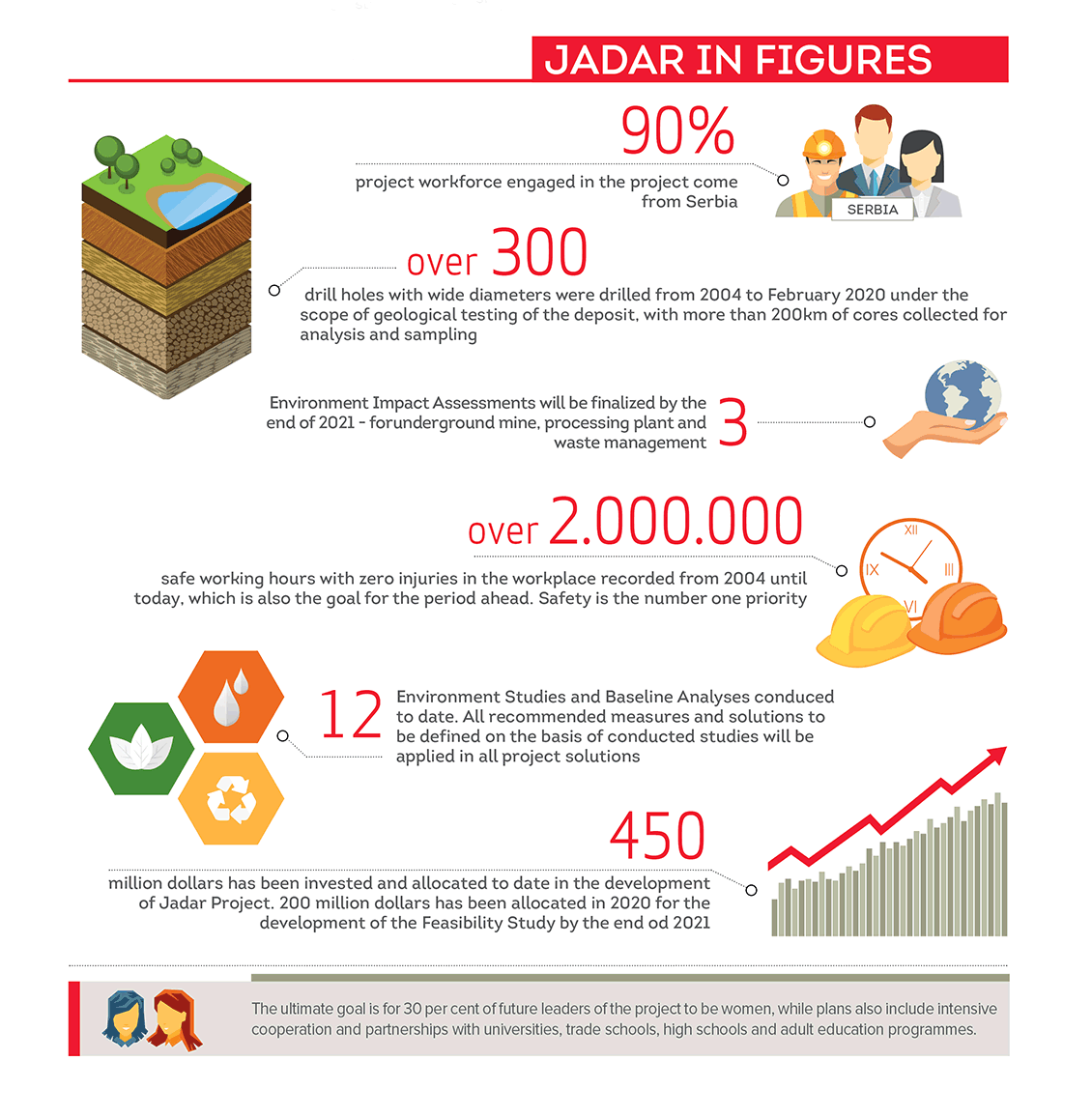

Rio Tinto has had a presence in Serbia, where it has been present since 2004 – when it discovered the unique Jadarite mineral near the town of Loznica – starting the Jadar Project. Since then, Rio Tinto has carried out 300 drilling operations as part of its geological research on the ore body, using the best available methods and technologies, and established technical cooperation with more than 90 domestic and international partners on a variety of areas.

Rio Tinto will invest an additional $200 million in the feasibility phase of project development, which will bring the total invested to $450 million till the end of 2021. The project is expected to create more than 2,000 jobs during the construction phase. Construction could begin in early 2022 and last approximately four years. When it starts operating at full capacity, Jadar is expected to employ more than 700 high skilled workers. The project has set an ambitious goal for 30 per cent of future project leaders to be women, and development plans also include intensive cooperation and partnerships with universities, trade schools, high schools and adult education programmes

JADAR IS MORE THAN A MINING PROJECT

Jadar is the only place in the world where you can find jadarite – a lithium sodium-borosilicate mineral. Lithium is a key component of batteries for electric vehicles and energy storage, and borates are an indispensable ingredient of many household products.

Of Jadar’s three major products (lithium carbonate, boric acid and sodium sulfate), the most important will be lithium carbonate – a key input for the production of electric vehicle batteries. Lithium is a material of the future, a material that’s vital to the development of the future low-carbon economy, and Jadar is more than just a mining project. It will be a modern underground mine, with accompanying processing technology and infrastructure, built with a sustainable approach to environmental protection.

The Jadar Project team is dedicated to understand our communities priorities and concerns and share all information about the project and its impacts in our two Rio Tinto Information Centres in Loznica and Brezjak. Over the past 12 months alone, 19 Open Day events have been held with the community, covering topics including environmental compliance, biodiversity, cultural heritage, land acquisition workshops and supplier development.

The Jadar project does prioritizes environment protection. It is of strategic importance, both for the exploitation and production of lithium, and for the development of the green economy, Serbia’s GDP and new jobs. The Jadar project will be based on modern technological exploitation and production, which – according to Marnie Finlayson, Rio Tinto Managing Director for Borates and Lithium – will also contribute to preserving the environment.

Twelve environmental studies have been conducted since research on the project began, covering air and water quality, noise pollution, waste management, project impact on soil, biodiversity etc. Three Environment Impact Assessment Studies will haven be completed by the end of the Feasibility study phase – for the mine, processing plant and waste management solution. All project solutions will apply all recommended measures and solutions defined on the basis of these studies, to ensure safe and sustainable operations and long term benefits to the communities, Serbia and the company.

FINDING THE BEST POSSIBLE SOLUTIONS

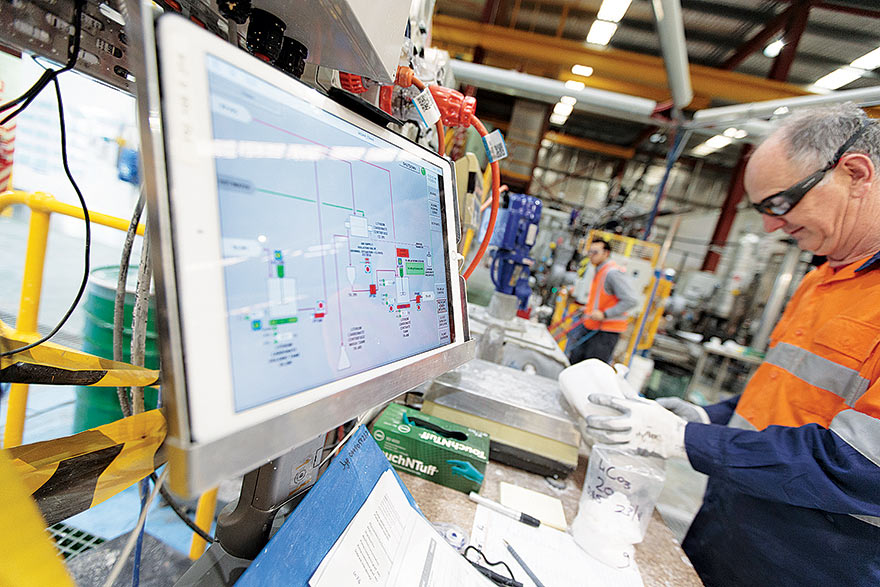

Rio Tinto is committed to finding the best ways to minimise potential impacts on the environment and the community. The industrial waste from processed ore has undergone significant improvements as the project has advanced in terms of knowledge and the confidence in the processing technology. The Serbian and international team of technical experts, chemical and processing engineers spent several years trying to find stable and reliable ways to convert the slurry waste into filter cake as a more sustainable solution. And they succeeded!

They strive to minimise waste generation and at Jadar will be using approximately 20% of generated waste as backfill in the underground mine, while Jadar team is committed to constantly improve the waste solutions in order to minimize footprint.

PLANNING FOR THE FUTURE

The way Rio Tinto manages its plants is vital for the future of local communities, both during operations and after work has ceased. The company considers the decommissioning of a mine before it even opens, because everything will be returned to its original state. The way Rio Tinto gradually rehabilitates land can be seen in places like Richards Bay Minerals, KwaZulu-Natal in South Africa or the bauxite mine in Queensland, Australia. A great example of operating sustainably in challenging environments Is the Diavik diamond mine, located on an inaccessible island near the Arctic Circle in northwest Canada. The mine was designed with consideration for its ultimate closure in mind. The site’s buildings can be removed, and after excavation concludes the embankments will be renewed, while the open pits will be filled with lake water.

Rio Tinto continues to seek ways to additionally process mineral waste, including tailings, in the coming years, and will also strive to increase the percentage of low-carbon renewable electricity used in its operations.