Rio Tinto has been responsibly developing “Jadar” for a full 17 years through the various stages of planning, design and approvals. We are committed to partnership, with the Government of Serbia, the local government and our communities. We have a joint commitment to responsible mining and operating to the highest environmental standards.

Our goal is to develop the project hand in hand caring for and preserving the environment, says Vesna Prodanović, who approaches the further development of Jadar with a great personal motivation and tenacity to build something of great value to both Serbia and the world.

It sounds really unbelievable that one of the world’s most important lithium deposits is located in Jadar… If that is indeed the case, then we aren’t even aware of how great a chance this represents for the economic development of Serbia as a whole…

Lithium is increasingly called the material of the future, because it has a huge role to play in the further development of modern society. The development of modern lithium-ion batteries represents a genuine revolution in energy use, not only in terms of Electric Vehicles and the supporting industries, but also because of its use in the devices that we use on a daily basis, such as phones and laptops.

I think we are becoming aware of how great the potential is for Serbia, considering that we have one of the world’s most important deposits of lithium and also boron. However, in order for us to develop that potential in the right way and achieve the best results, it is necessary to make a long-term commitment, work in real partnership, and leverage global expertise, in order to continue our progress from exploration, surveys and studies to developing this project.

What are your employment plans like, given that we know that more than 2,100 workers will be engaged during the phase of constructing the mine and processing plant?

The most valuable assets of our company are our people, and we understand that the success we achieve is linked directly to the abilities and engagement of our employees. That’s why the development of knowledge and skills is a priority for us. We are highly appreciative of the fact that Serbia’s education system and work ethic are very strong, which gives us a distinct advantage while we work on the development of employment plans and strategies for future skills and roles, from construction through operation. Jadar is planned as a mine of the future, using cutting-edge technology. The project will need a wide range of new skills and produce products key to a low carbon future.

We already have a team of talented, highly-educated Serbian experts who are working on the project. We are working towards maintaining 90% of future employees also being from Serbia, as is the case today. We need not only miners and chemical engineers, also innovators, entrepreneurs and talented youth with passion and vision. That’s why we’re planning partnerships with universities, secondary schools and adult education systems. We will try to demonstrate, with our own example, what modern and sustainable mining in the 21st century looks like.

In order for us to support our current and future employees, we will develop training programmes for the unique skills and specific domains we will require, using state-of-the-art training methods and equipment, including AR/VR and process simulators.

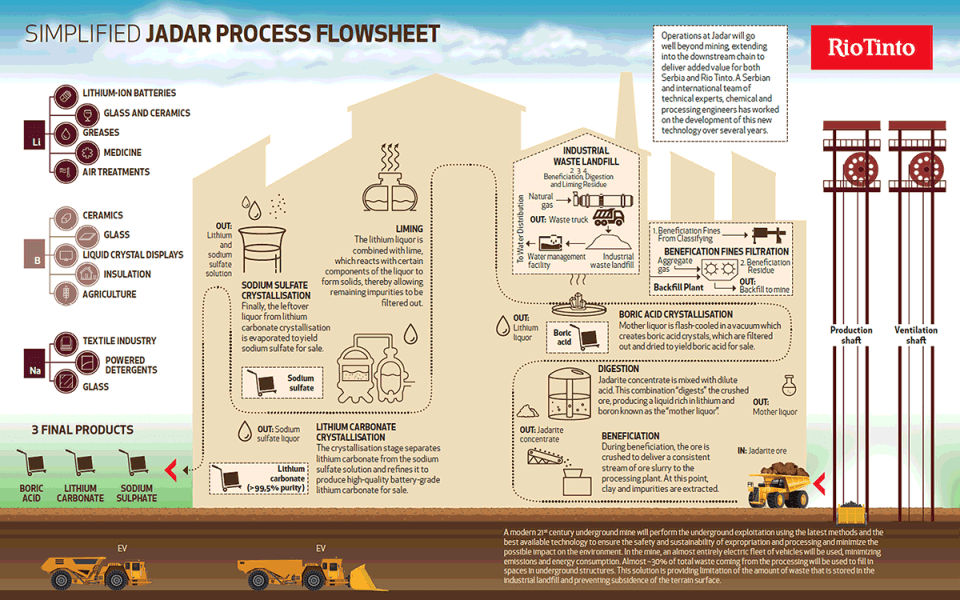

The processing of jadarite will be performed in a modern industrial plant, using a unique, innovative and stable technology

Is the public aware that this project’s development could bring Serbia a chance to entice other investors, as a green economy destination?

That is well recognised by the national Government, the local government and, increasingly, by our host communities. The world is also closely following Jadar and the way Serbia is developing this potential. Jadar can strengthen and reposition Serbia on the world market as an excellent investment destination for the implementation of large, successful projects.

Jadar is a first for Serbia – an entirely new project, which will use many technologies and processes for the first time. Here, communication is key. We pay special attention to this within the company, we believe that if we aren’t able to explain what we do in a simple way then we aren’t doing it right. As with any new technology or development, there will be concerns about its impact – particularly ecological and environmental. One of the most important tasks for our team at this stage is to present an accurate picture of all aspects of the project. We are certain that, with the results achieved to date, we have the expertise to build this project as a responsible, safe and environmentally sound way.

Is it accurate that your company has developed innovative technology that has improved significantly over a series of years? Is it possible for an environmental challenge to exist that cannot be resolved in the 21st century?

Jadarite is a unique mineral that’s found only in Serbia, it was discovered in the vicinity of Loznica in 2004.

It required the development of a completely new technology for processing. Jadarite will be processed in a modern industrial plant, using a unique, innovative and stable technology that’s been developed by a team of leading domestic and foreign experts – that is has been proven at a pilot plant purpose-built in Rio Tinto’s Australian operations. Around 2,000 tests were performed in order for us to ensure that we’ve developed the optimal solution to create the final industrial products of lithium carbonate, boric acid and sodium sulphate.

We’ve also had five independent audits conducted by relevant experts in different fields in order to validate the entire process and we are very satisfied with the results achieved. We invested significant resources and a lot of time before confirming that the processing technology is technically sustainable and stable.

The world continues to be confronted by challenges in the 21st century, but from my point of view none of those challenges are impossible. We’ve approached every aspect of the project’s development from the perspective of long-term sustainability. We encountered many technical challenges, but we continued seeking solutions so we could ensure good results. We’ve achieved great success in the area of industrial waste, which has been totally transformed, through the development of technology, from fluid, sludge waste to a solid mass – which allows much safer storage with a much smaller footprint.

We will continue investing in systems and solutions that will enable the safe implementing of production activities, taking care to minimise the impact on the natural environment and the surrounding area. According to current estimates, investments in environmental protection will total a minimum of US$100 million, with around US$40 million to be invested in the water treatment plant alone. Systems for monitoring impacts and regular measurements are also a priority, and all of this leads to us being able to say with certainty that Jadar will only be considered for development f it meets all the conditions to be a safe and sustainable industrial activity.

Investments in environmental protection will total a minimum of 100 million dollars, with around 40 million dollars to be invested in the water treatment plant alone

Minister Mihajlović has repeated on multiple occasions that everything that’s being done must be undertaken with the highest degree of protection, because there is no amount of money and investment that can justify the destruction of the environment. How would you comment on that?

We are in complete agreement! Our priority is safety, responsibility and a fair relationship towards the environment in all region where we operate. We have been developing the Jadar Project responsibly for a full 17 years, bringing sustainable planning and design solutions in the process. We are developing this project in partnership with the Government of Serbia, the local government and communities, and we have a joint commitment to protecting the environment, as one of the preconditions for the project’s further development.

Our approach shows that responsible mining and processing is indeed possible with care for the environment. We will always strive to minimise any potential negative impacts, as well as optimising the long-term benefits that we share with the community.

How is it possible to reassure citizens and environmentalists who believe that this project’s development will destroy many watercourses, including the River Jadar? Do they know that you will install a state-of-the-art wastewater treatment plant? What will you do with the waste generated during the exploitation and processing of jadarite?

Let’s be clear – this project will not destroy any watercourses. All water used during production activities will be used several times, and that will be done in a closed, circular system, and prior to surplus water being released into the environment, specifically into the Jadar river, it will be treated in a water treatment plant, where it will reach the legally specified quality before being discharged into the river. Approximately US$40 million will be invested in the water treatment facility.

When it comes to waste, the mine and processing plant will produce two types of waste: rock material from the underground mine, and industrial waste following the processing of jadarite concentrate. This waste will be converted into solid filter cakes that will be stacked, levelled and compacted at the landfill site.

A certain part of the total waste from processing plant, approximately 30 per cent, will be used in a mixture that’s specially made for filling the excavated space within the underground mine. This solution will simultaneously contribute to reducing the amount of total waste deposited on the surface and prevent the possibility of land subsidence.

We are committed to transparency and engagement. We have two information centres, in Loznica and Brezjak, but we are aware of the need for us to do more to ensure that accurate information reaches all stakeholders, most importantly our host communities. We are working on this with diligence and will complete this task and engage even more intensively.

Rio Tinto will strive towards ensuring that 90% of those engaged in the project in the future also come from Serbia, as is the case now

You’ve worked on projects in Russia, Nigeria and Belarus and large and complex projects in Serbia. You spent a quarter of a century working in construction, at Energoprojekt and Bechtel, dealing with projects above the ground, while now you’ve decided to “delve” under the ground. Has this change suited you?

That’s interesting insight, I must admit, and thank you for that. I must say that I’m extremely grateful for the experience I gained while working for Energoprojekt and Bechtel, and not only for the experience that built me professionally and personally, but also for the time I spent with a great team and colleagues, working on projects that really do rise high above the ground. All of this served and helped to ensure that I can today state with certainty that I approach the further development of Jadar with a great desire and perseverance for us to bring something that’s valuable to Serbia and the whole world.

I’m grateful for the opportunity I’ve been given to work on such a significant and unique endeavour as Jadar and I feel proud that Serbia has such an opportunity. However, in order to successfully realise that potential we need to continue developing and strengthening our existing partnerships at all levels, to build new ones and continue cooperating with all parties.

Changes are always welcome. Jadar is much more than a mining project – actually, bigger part of the project are complex industrial plant with landfill and associated infrastructure, and each part of the project is equally important.

Prior to your arrival, the previous head of this project was also a woman, Marnie Finlayson. Does this mean that ever more women are occupying important positions in the world of mining?

Yes, and that’s wonderful. But there is still a lot of work ahead of us in that segment and I consider it necessary for more women who are top professionals and experts to find themselves in the positions that they deserve, both in this and other industries. There is a long-standing prejudice that claims mining, construction, mechanical engineering and technology are “men’s jobs”, but I believe this concept was overcome a long time ago. I will personally dedicate myself and advocate for this, and that is one of this project’s goals – for gender equality and the empowerment and development of all talents, especially women, in our industry to become a practise that will be followed by others.